-

Monday - Friday, 8:00am- 5:00 pm

- +86-13306182632

- meixiaobo@ylsl.net

Monday - Friday, 8:00am- 5:00 pm

New Materials – (III) Polymer Materials – 4. Preparation Technology of New Fibers and Composite Materials

Core competitiveness - one-time molding of multiple materials

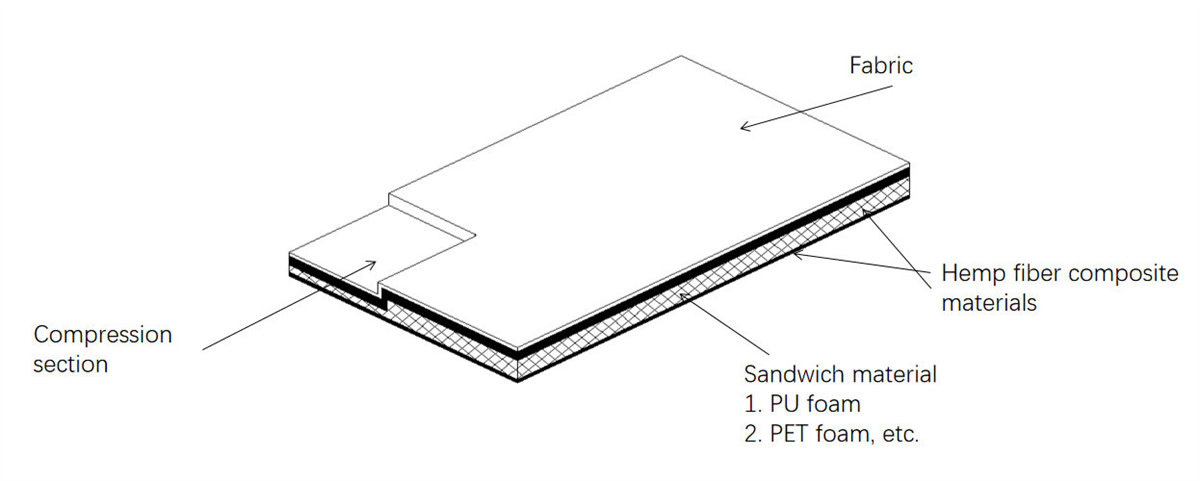

One-time molding technology of multiple materials

One-time molding of fabric and skeleton (with strong sound insulation and sound absorption effects, low weight, high strength, and good shaping effect)

Core competitiveness - hollow board technology

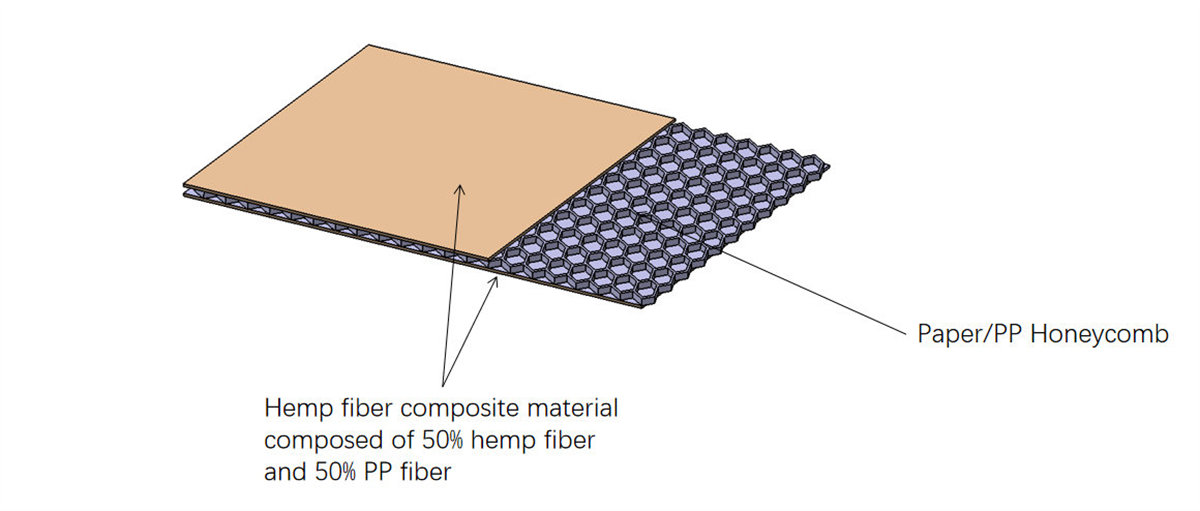

Hollow technology

Hollow molding can be achieved using natural hemp fiber materials

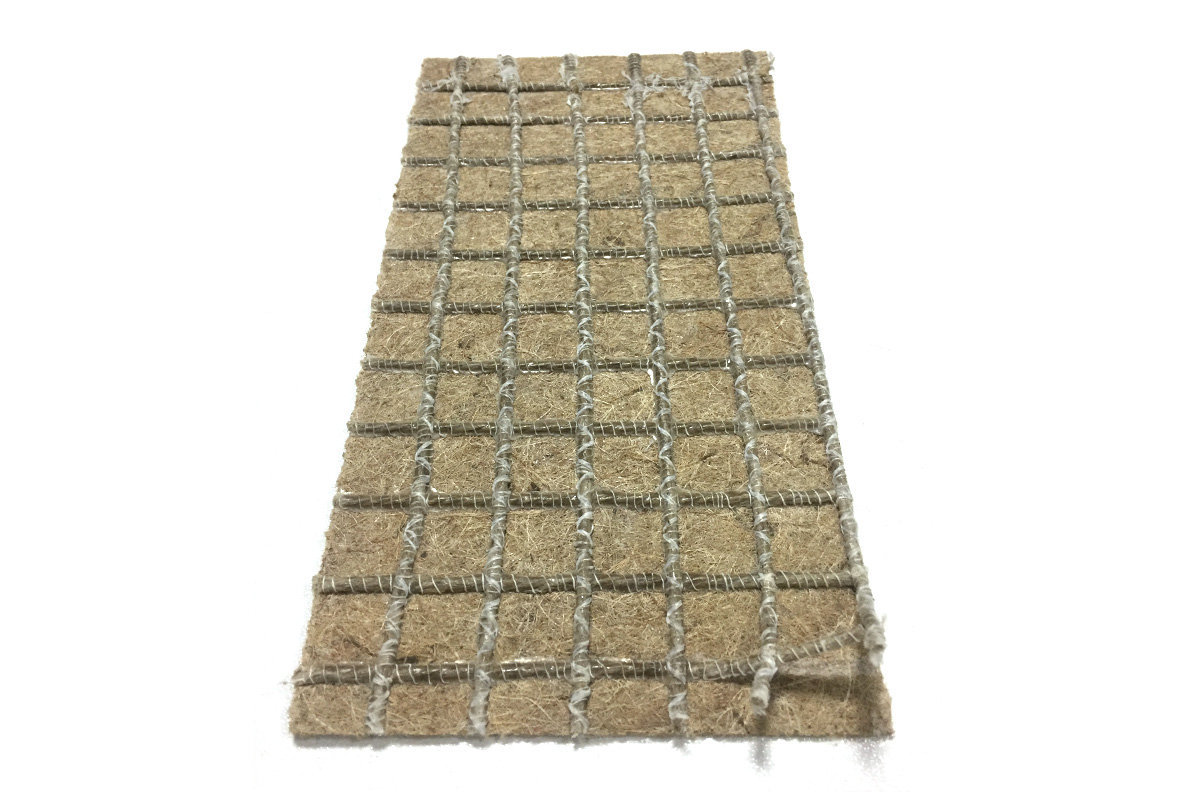

Core competitiveness - grid-reinforced composite hemp board technology

Grid-reinforced composite hemp board

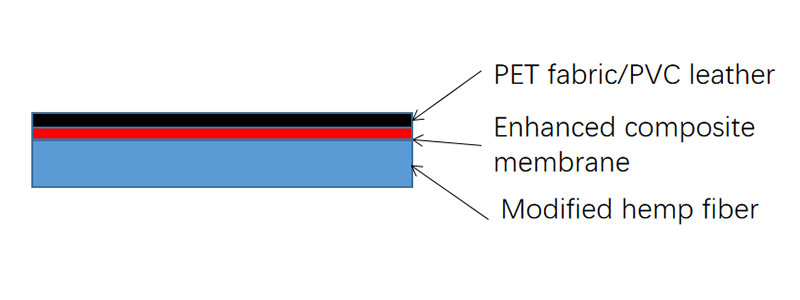

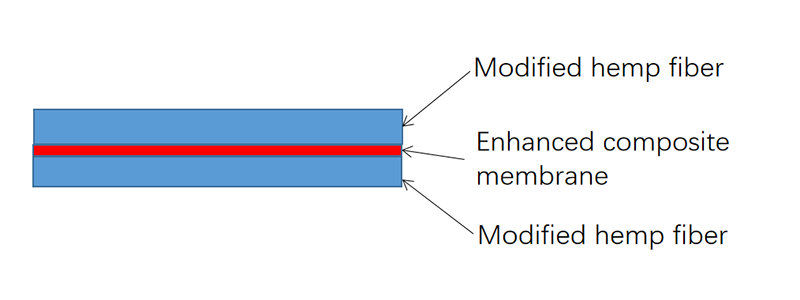

Core competitiveness - composite membrane strength enhancement technology

Light-weight hemp board composite membrane strength enhancement technology

It can make the natural hemp fiber material 50% stronger in bending strength than ordinary hemp board in the same weight hemp board state, and can be baked at high temperature (the conventional hemp board baking temperature is 230℃, this state can accept 280℃-300℃), making the production efficiency higher

Core Competitiveness - Material Manufacturing Capability

Has two production lines: Qingdao Textile Machinery Carding and BONINO Air Laying

Hemp fiber, waste spinning fiber, PP/PET fiber felt and board

Core Competitiveness - Molding and Manufacturing Capabilities

We have imported and domestic forming presses, riveting and welding machines, full presses equipped with manipulator heating tooling and automatic feeding ovens