-

Monday - Friday, 8:00am- 5:00 pm

- +86-13306182632

- meixiaobo@ylsl.net

Monday - Friday, 8:00am- 5:00 pm

Jiangyin Yanli Automotive Trim Co., Ltd. was founded in February 1994. The company is located in the economically prosperous central area of the Yangtze River Delta. At present, the company has a registered capital of 23.6 million yuan, covers an area of 25,600 square meters, and has a construction area of 15,000 square meters. The company has 2 fully imported automatic hemp felt production lines from Italy, 2 domestic hemp felt production lines; 1 set of fully automatic hemp board hot rolling composite machine imported from Italy, 3 domestic continuous hot pressing composite machines; more than 20 automotive interior parts forming (punching) presses, and 2 automotive trim injection production lines. Annual production of 7,500 tons of bamboo and hemp natural fiberboard, 2.5 million sets of automotive interior parts, and 400,000 sets of seat backboards.

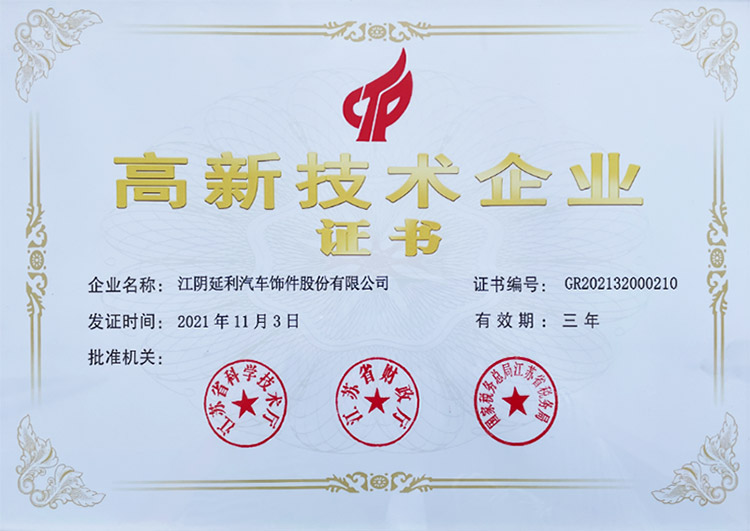

The company became a high-tech enterprise in Jiangsu Province in 2005, and established the Jiangsu Province (Yanli) Natural Plant Fiber Composite Material Engineering Technology Research Center in 2009. It currently has 12 independent invention patents, 1 national key new product, and 7 high-tech products. The company has been committed to the innovative research and development of natural plant fiber composite materials for a long time. It has cooperated with the Wood Industry Research Institute of the Chinese Academy of Forestry and Nanjing Forestry University of China to establish the Jiangsu Natural Plant Fiber Material Research Center and the Academician Workstation. It has researched and developed a series of products based on bamboo and hemp natural fibers. The automotive interior materials have been widely used in domestic mid-to-high-end cars and have won unanimous praise from the industry. It has also led the formulation of industry standards for interior materials in China's automotive industry. After six years of dedicated research, the lightweight decorative floor for high-speed rail transit has been successfully installed on the "Fuxing" of CRRC Corporation. The lightweight and high-toughness material characteristics will contribute to the "faster" of China's high-speed rail. So far, the company has successfully passed the IATF16949 quality management system/TS22163 quality management system/ISO14001 environmental management system/OHSAS18000 occupational health and safety management system/safety standardization management system certification, and 6 automotive interior products have passed the national 3C mandatory certification.

The company adheres to the development concept of "gathering the wisdom of experts from all over the world and creating world science and technology innovation", strives to build the Yanli brand of "first-class talents, first-class technology, first-class management, and first-class quality" in the industry, and promotes the corporate spirit of "integrity, diligence, excellence, and practice". Guided by continuous innovation of material technology and enhancement of customer value, the company leads the application of natural bamboo and linen fiber composite materials to deeper and wider fields, actively explores the application market of domestic and foreign high-end automotive interior materials, high-end home and hotel decoration materials, high-speed rail transit interior materials, new energy vehicle seat backs, etc., and builds the company into a first-class professional manufacturer of bamboo and linen fiber composite materials, and better serves customers and gives back to society with greener and more environmentally friendly products.

Jiangsu famous brand products, Jiangsu Province star enterprise, provincial high-tech enterprise, Designated supplier for military and government procurement, National standard setting unit for hemp fiber composite materials for automobiles

IATF16949 (automotive manufacturing) quality management system certification, IRIS (International Railway Industry Standard) quality management system certification, China Environmental Labeling Product Certification, ISO/14001 System Certification, ISO45001 System Certification, 3C Certification