-

Monday - Friday, 8:00am- 5:00 pm

- +86-13306182632

- meixiaobo@ylsl.net

Monday - Friday, 8:00am- 5:00 pm

Key technologies:

1. High-temperature penetration enhancement technology: The plant hemp fiber is modified and enhanced by using a penetrant working fluid containing JFC penetrant, which greatly reduces the content of lignin, pectin, wax, and nitrogen-containing substances in it, preventing it from chemically reacting with oxygen in the air, avoiding or reducing the production of harmful substances such as aldehydes and benzene, effectively eliminating the odor hazards of formaldehyde release and VOC, and having good environmental protection.

2. Airflow forming technology: The airflow makes the mixed fiber more uniform in all directions, thereby improving the overall strength of the hemp fiber composite board.

3. Graphene high-efficiency heat transfer technology is used for heating to reduce power consumption, while reducing the gram weight and increasing the tensile strength, meeting market requirements and meeting the development trend of lightweight and environmentally friendly home decoration.

Material introduction:

(1) Environmentally friendly hemp fiber is used as the base material, and the composite fabric is made by a one-time hot pressing molding process.

(2) The hemp fiberboard material is a textile fiber, which is environmentally friendly and degradable.

(3) Due to the process characteristics of the product, it can achieve higher toughness and safer collision effect through a multi-layer structure.

Material characteristics:

This product uses natural hemp silk and PP fiber silk as the main raw materials. It is light in weight, low in density, high in strength, impact resistant, low in cost, environmentally friendly, and has good sound insulation and heat insulation properties; it is easy to form, has high tensile and tensile strength, and has good chemical fiber bonding after heating and pressurization, without using any glue adhesive.

Scope of application:

Widely used in passenger cars, commercial vehicles, buses and other car roofs, inner door panel frames, rear shelves, luggage compartment inner panels and other interior parts substrates;

Advantages of hemp fiber composite materials:

Advantages of hemp fiber composite materials 1: Environmental protection

1. Ecological protection performance: short growth period;

2. No "three wastes" in the production process;

3. No adhesive in the molding process;

4. Renewable and recyclable;

5. The scraps in the production process can be recycled

6. Waste parts can also be recycled

7. Compared with PP materials:

For the same weight, the strength is increased by 5% to 10%.

For the same strength, the weight is reduced by 15% to 20%.

Advantages of hemp fiber composite materials 2: Easy to form

Low-pressure molding

The pressure required during the molding process of molded parts is relatively small, and 100-250T pressure can be used for molding.

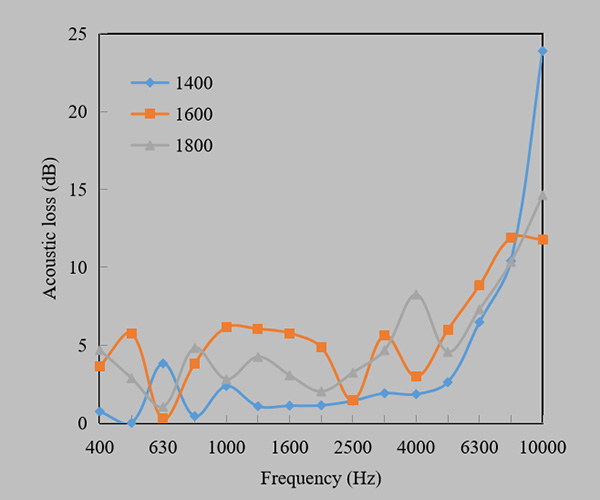

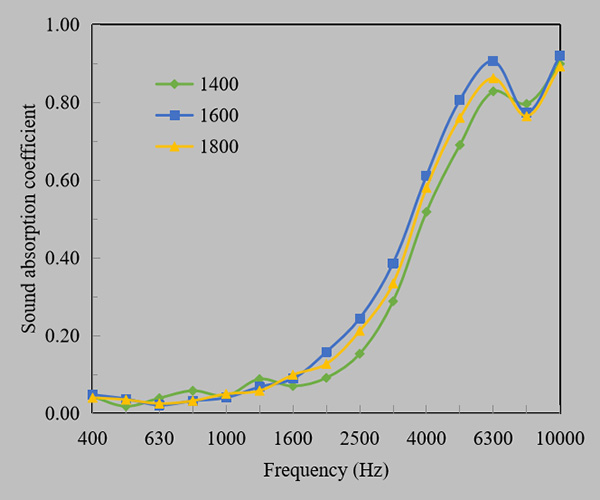

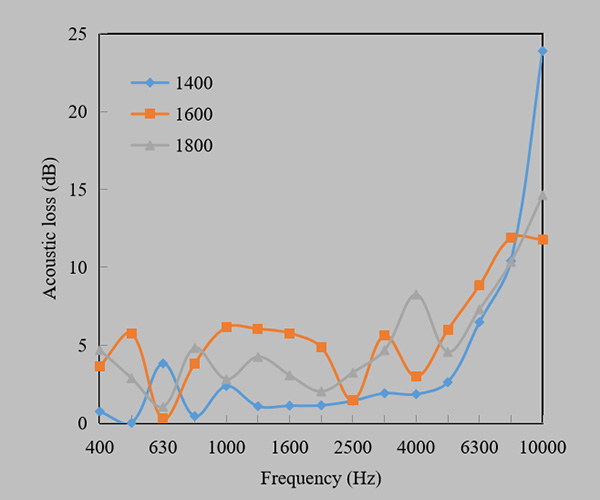

Advantages of hemp fiber composite materials 3: heat insulation and sound absorption

There are many cavity structures inside the hemp fiber composite materials, which are conducive to sound absorption and sound insulation

|

|

| Sound absorption performance of hemp fiber materials with three surface densities | Sound insulation performance of hemp fiber materials with three surface densities |

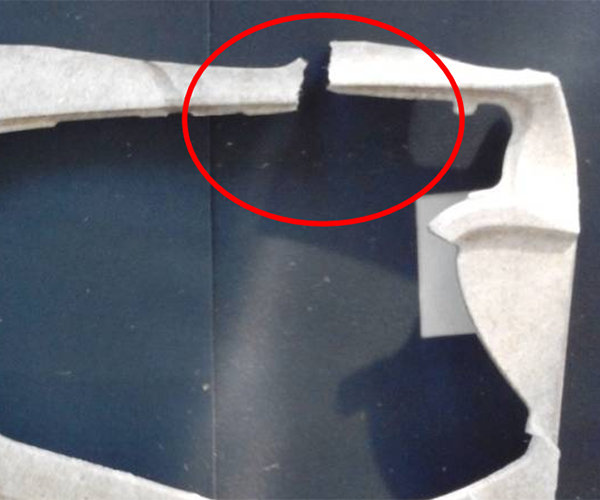

Hemp fiber composite material advantage 4: safety

| Plastic brittle fracture characteristics. Plastic produces sharp corners, causing secondary damage | Hemp fiber composite materials have non-brittle fracture characteristics. It has the function of absorbing energy and avoiding secondary damage |

|

|

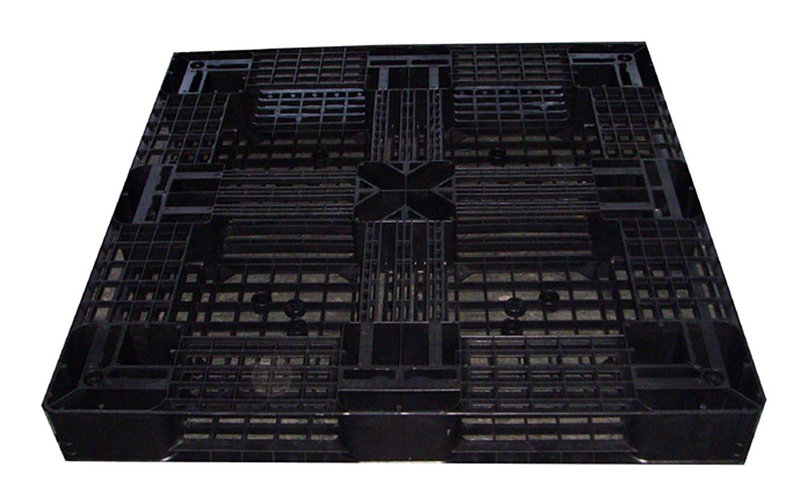

Hemp fiber composite material advantage 5: Recyclable

|

|

|

|

|

|

| Special waste recycling equipment | Hemp fiber particles | Recycling: plastic pallets and keels |

Special equipment for crushing and granulation is completed in one go

Make hemp fiber particles that can be used for reprocessing

Particle application: extrusion molding, injection molding